Welcome to MRT

Welcome to MRT

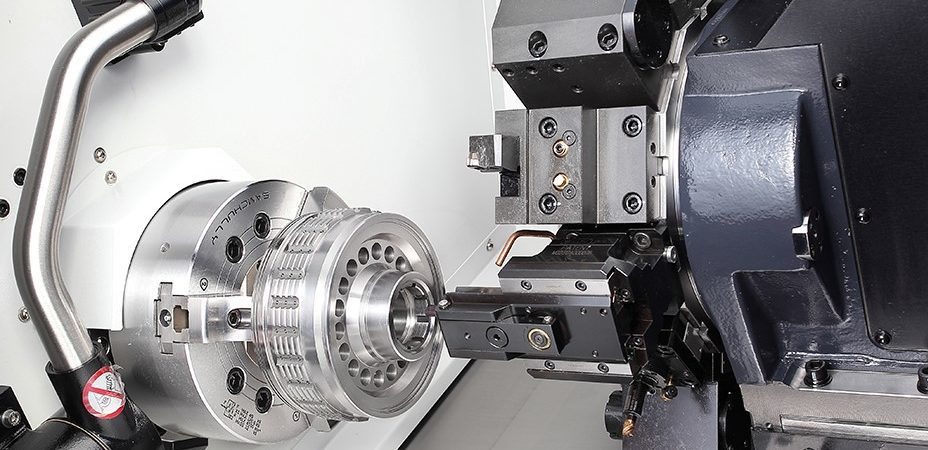

MRT Manufacturing & Reface Technology is headquartered in Billings, Montana supporting the Oil & Gas upstream and downstream sectors, mining, agriculture, construction, highway equipment, architectural to custom projects. We house CNC machining capabilities, water jet cutting, 3D printing, and design services utilizing state-of-the-art Solid Works CAD design studio to take the concept to high precision working parts.

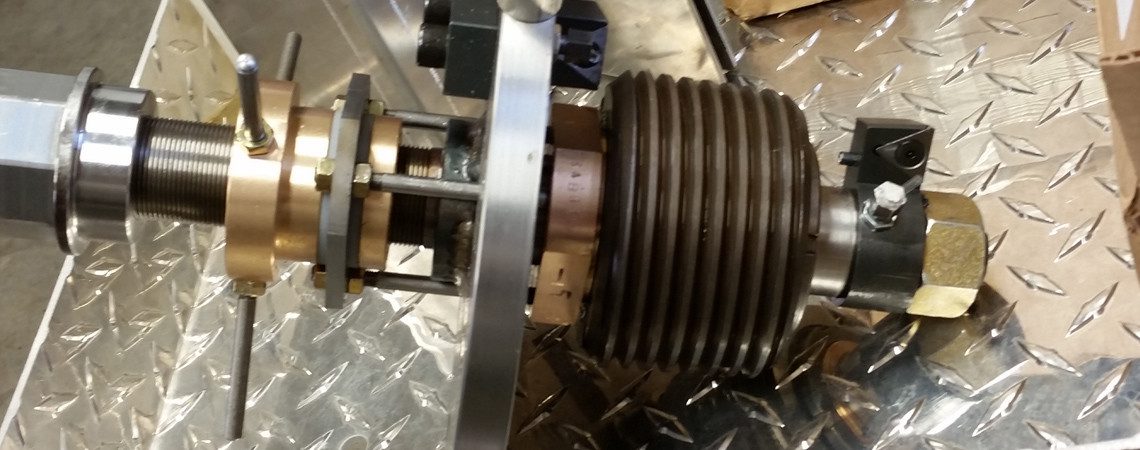

MRT is also the home to our Patented Mobile Lathe Refacing Technology used in maintaining drill pipe sealing surfaces in the field. We specialize in double shoulder, high toque connections that meet API, DS1, and other relevant industry standards in the oil & gas industry. Our patented Lathe Refacing System is second to none, bringing “precise tools for a precision cut™” to the inspection and drill pipe repair industry.

We also specialize in manufacturing API rotary drilling subs and lift subs to cross over subs that meet API Spec Q1 compliance. Utilizing Gagemaker’s JSS® Thread Inspection System for Rotary Shouldered Connections, we assure highly accurate API connections proven to perform in the field. Our Milling Tools used in oil & gas well-bores are durable and reliable. We can produce Thru-Tubing Mills for plug removal to junk mills to remove debris from the wellbore and custom build any mill to your desired specification.

MRT™ has established the precision standard in rotary & double-shouldered connection lathe refacing through precision-crafted tools and outstanding service. We are proud of the solid relationships we have built over the years with our clientele across the globe and look forward to growing with you through quality products and commitment to service excellence.

Welcome to MRT

Welcome to MRT